Nabertherm LHT 01/16 Turbo Fire | High-Temperature Speed Sintering Furnace for Translucent Zirconia

Unmatched Speed & Precision for Chairside and Lab-Based Sintering

The Nabertherm LHT 01/16 Turbo Fire is a cutting-edge high-temperature speed sintering furnace, engineered for the rapid sintering of translucent zirconia crowns in under one hour. Ideal for chairside production in dental practices and urgent cases in dental laboratories, this furnace delivers unparalleled efficiency, precision, and convenience.

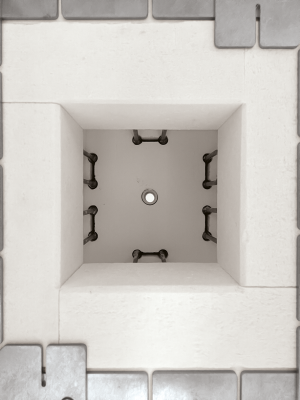

With a maximum temperature of 1600ºC, six high-quality molybdenum disilicide heating elements, and all-round chamber heating, the LHT 01/16 Turbo Fire ensures exceptional temperature uniformity for consistent, high-quality zirconia restorations.

Key Features & Benefits

✅ Ultra-Fast Sintering in Under 1 Hour

✅ Superior Heat Uniformity & Process Stability

-

Six high-quality molybdenum disilicide heating elements provide balanced, rapid heating while minimizing chemical interaction with sintered materials.

-

All-around furnace chamber heating ensures perfect temperature distribution, eliminating inconsistencies in zirconia restorations.

✅ Motorized Lifting Table for Easy Operation

✅ Innovative Insulation for Fast Cooling

✅ Advanced Touchscreen Control & Remote Monitoring

-

6.8-inch high-contrast touchscreen for intuitive program input & monitoring.

-

Free MyNabertherm App allows for real-time online monitoring via mobile devices, providing push notifications for process updates and alerts.

✅ Seamless Digital Integration & Process Documentation

-

50 customizable programs with 40 segments each, allowing for precise sintering customization.

-

NTLog Basic & NTGraph software for USB-based process data recording & analysis.

-

NTEdit freeware enables Excel-based programming for easy workflow optimization.

✅ Universal Compatibility & Safety-First Design

-

Fully compatible with blanks from all leading zirconia manufacturers.

-

RCF-free insulation materials meet European safety regulations, ensuring a safer working environment.

Technical Specifications

|

Feature

|

LHT 01/16 Turbo Fire

|

|

Max Temperature

|

1600°C

|

|

Working Space Dimensions (W × D × H)

|

65 × 65 × 30 mm

|

|

Charging Area (W × D)

|

85 × 85 mm

|

|

Maximum Capacity

|

Up to 3 single zirconia crowns per cycle

|

|

Outer Dimensions (W × D × H)

|

295 × 405 × 565 mm

|

|

Power Consumption

|

2.9 kW

|

|

Electrical Connection

|

1-phase (Available in 200V, 208V, 220V - 240V, 1/N/PE or 2/PE)

|

|

Weight

|

25 kg

|

|

Heating Time to Tmax -100K

|

20 minutes

|

What’s Included?

✔ LHT 01/16 Turbo Fire Furnace Unit

✔ Starter Set for Charging (Technical Ceramic Batch Container & Spacers)

✔ Motorized Lifting Table for Easy Operation

✔ Exhaust Vent in the Ceiling

✔ Type S Thermocouple

✔ NTLog USB Stick for Process Data Recording

✔ NTEdit & NTGraph Software for Program & Process Analysis

✔ MyNabertherm App for Remote Monitoring & Alerts

Why Choose the Nabertherm LHT 01/16 Turbo Fire?

✔ Fastest sintering time available – Complete zirconia crowns in under 1 hour for instant chairside restorations & urgent lab cases.

✔ Exceptional precision & repeatability – Advanced heating elements & thermal uniformity ensure perfect results every time.

✔ User-friendly digital controls – Intuitive touchscreen & remote monitoring capabilities for maximum workflow efficiency.

✔ Optimized safety & long-term reliability – Built with premium materials & compliance with European safety standards.

✔ Perfect for modern dental labs & clinics – Designed for speed, quality, and digital integration, supporting smart dental workflows.

🚀 Upgrade Your Sintering Workflow with the LHT 01/16 Turbo Fire – The Ultimate Speed Sintering Solution! 🚀

Tmax 1600 °C

1 - 3 single crowns can be sintered within an hour

Six high-quality heating elements made of molybdenum disilicide offer very good protection against chemical interaction between charge and heating elements

Very good temperature uniformity due to allround heating of the furnace chamber

MyNabertherm App for online monitoring of the firing on mobile devices for free download see page 48